VersaTherm: Elevating Culinary Innovation in the Industrial Kitchen

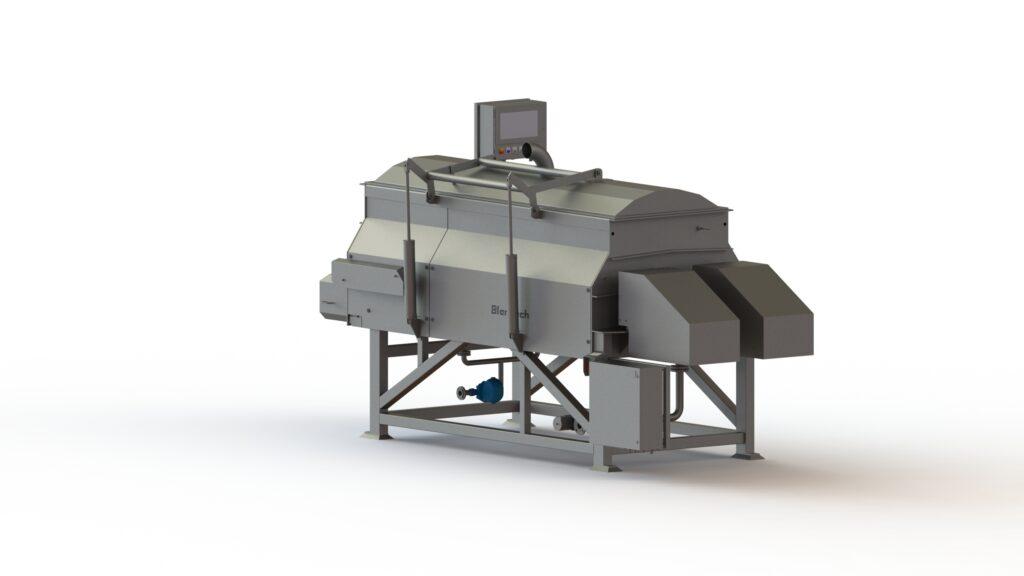

The VersaTherm is a pinnacle of innovation in the industrial cooking sector, skillfully handling an extensive range of culinary applications from the preparation of rich stews and intricate sauces to the creation of diverse international dishes. Similar to the Blentherm, what sets the VersaTherm apart in food processing environments is its unparalleled ability to adapt to various cooking methods within a single recipe. It starts with a sauté to cultivate depth of flavor and color, followed by the addition of liquids, showcasing its essential role in versatile cooking processes.

Designed with efficiency and space optimization in mind, the VersaTherm is particularly adept at processing highly viscous products that challenge traditional single agitation systems. These products, prone to poor mixing and barreling, are well handled in the VersaTherm due to its dual-agitator design. This innovative feature significantly increases the mixture’s contact with the cooker’s surface area, crucial for recipes requiring nuanced heat distribution, such as sautéing or those dependent on jacket heating rather than direct steam. By optimizing the surface area to volume ratio, the VersaTherm not only excels in these applications but also achieves notably faster cook times. This is especially advantageous for processes necessitating direct jacket heating, where even and efficient heat transfer is paramount.

Available in various sizes to suit any production scale, the VersaTherm is engineered for resilience, withstanding the thermal expansion and contraction of daily use through heating and cooling. Its construction quality is unmatched, featuring a metal jacket designed for durability and ease of repair. Advanced welding techniques ensure deep weld penetration, while meticulous hand polishing of continuous welds maintains a sanitary environment by preventing food particle entrapment.

The inclusion of a state-of-the-art software platform further distinguishes the VersaTherm. Tailored to the dynamic needs of contemporary food processors, this system facilitates a recipe-centric batch process. It guides operators through each step, allowing for variations in ingredient quality, thus ensuring exceptional batch consistency and repeatability. Additionally, the software’s advanced reporting and analytics capabilities provide vital insights into both ongoing and historical production trends, empowering manufacturers with the knowledge to refine processes and boost efficiency.